VERSION 1 – ORIGINAL IDEAS

Sweating Method

The first reverse microwave I thought of used the principle that we use when sweating. You take heat away from a surface but having a fluid on it that then gets removed through evaporation. This leaves the surface cool. This center canister walls spin inside of another circular wall. The inside wall that spins has a rug like surface on it.

Rubbing alcohol, distilled water, or other evaporation fluid can be pumped to the top of the wall to get the inside walls carpet like surface wet. Then when that center circular wall spins it throws away the fluid and the heat the fluid had captured from the center area. This idea is poor as you get more out of a normal refrigeration unit and the walls would be difficult to work with and in general would not cool things as fast as hoped for.

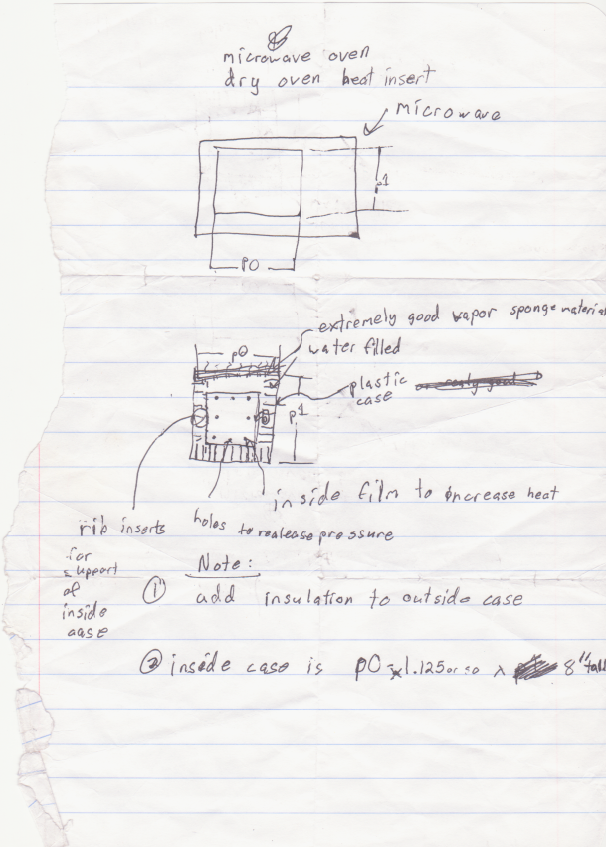

Pressure Difference Method

This method uses the idea of pressure drops causing cooling effects. Compressor driven refrigeration system use this principle. The idea of this reverse microwave concept is create a pressure difference inside an inside ribbed wall of the device. Water vapor would get trapped by a membrane and reused in the system. It is a mix between pressure drops and sweating method to create an increased temperature dropping method. This may or may not work. Not sure enough to be confident in the idea. Seems like it would require a compressor which is not cheap or small or cost effective in this scenario to get cold enough, fast enough.

VERSION 2 – WORKING MODEL (RAPID THERMAL EXCHANGE TECH)

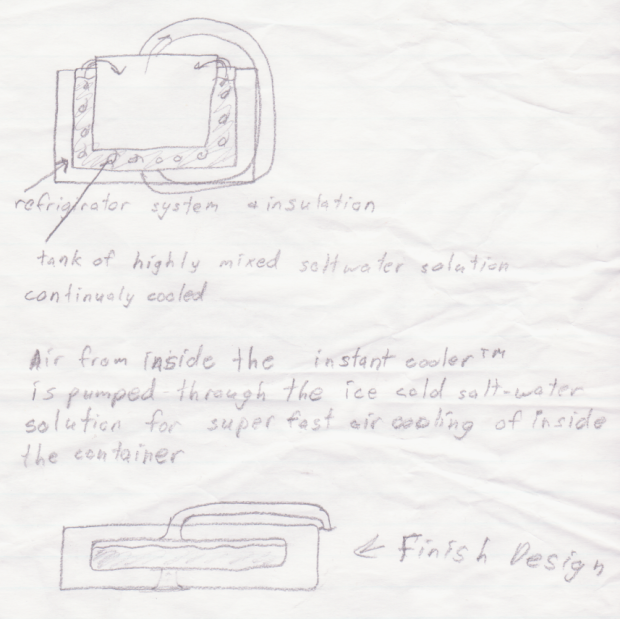

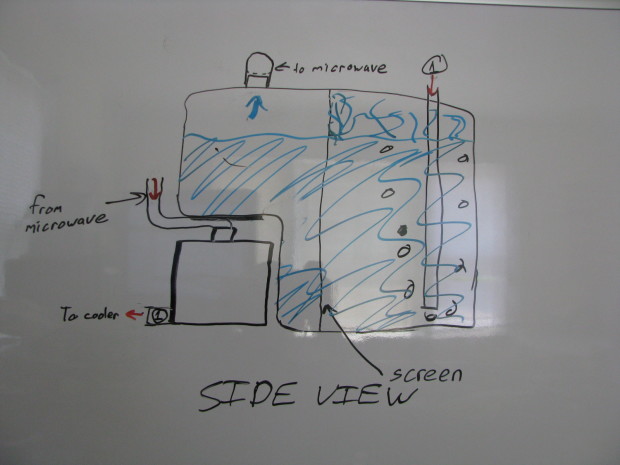

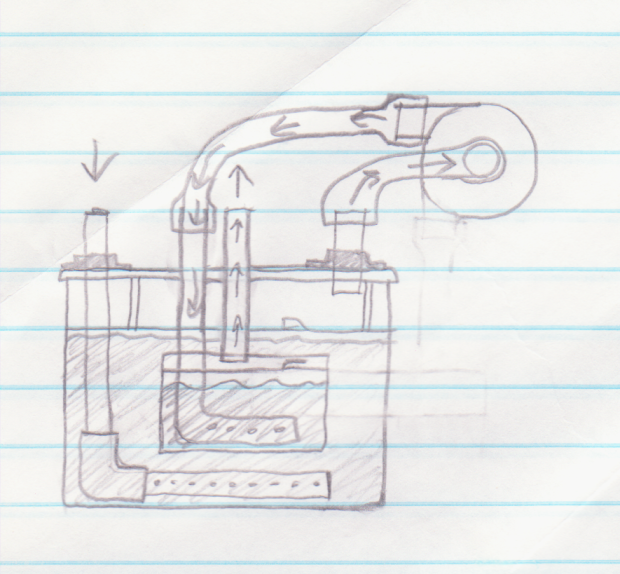

The air is pulled into the water tank via negative pressure from the top of the tank and positive pressure from the air input end of the water tank.

The holes are small and spaced with enough quantity that the air is more or less just flowing into the water at almost the same rate as if it was coming out of the end of the tube into the water. The air is just broken up into bubble format for the surface area that is gives the air that needs to have thermal changes applied rapidly.

There will most likely be multiple screens and most likely below the surface of the water to mitigate the reduction of air flow speeds and to eliminate bubble spitting and surface violence that would cause water droplets to be pulled into the cooling chamber where the food is.

Gore-Tex might be applied as a filter as well after the splash screen section. It is a material that lets air through but not water but will let vaporized water to pass through. It will wost likely be inline in the tube. It will be near enough and designed so that the droplets collected at that barrier are quickly and simply moved back to the water container. The want of the gas bubbles to hit the surface of the water removes a lot of the flow speed decrease issues. This will eliminate any water getting into the food cooling compartment.

These issues were thought about in the design process. The baffle was added after a test run was done. The test video posted had little to no droplets of water in the food compartment when it was done. Other than what was supposed to be in the cup.

Gore-Tex Technology Explanation

[youtube id=”5dqKe2IuNZs” align=”center” mode=”normal” autoplay=”no” maxwidth=”680″ grow=”yes”]

NOTE: That it uses convection but fast convection using the invented thermal exchanger that uses gas bubble surface area in fluid.

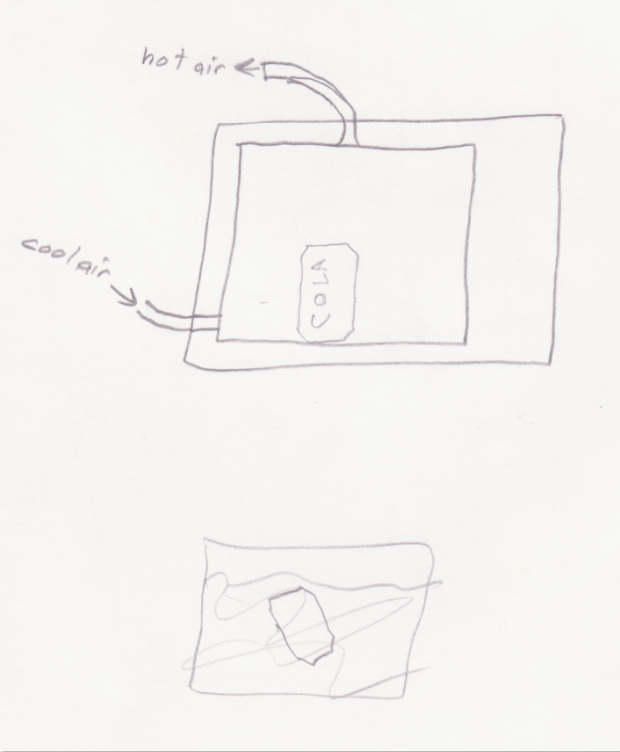

Convection seems to work pretty well to heat and cool most things. We have been using convection to heat our food in ovens for many generations. We use convection to keep our food and drinks cool in the refrigerator and freezer. You can drop the temperature or raise the temperature of things very quickly if the rate of air exchanged is very rapid and that the temperature of the air replacing the old warm air is very cold. This can be quite a hazard in very cold climates of the world. Quickly can get hypothermia in the water as well.

Water and air are both fluids but air is more insulation. However if it moves rapidly and is saturated in the temperature range you are trying to achieve, you can get similar results as if you were to use very cold water. We need things warm though.

Rapid Thermal Exchange Technology – Most people will use water-air thermal exchangers that use fins and pipes to change the temperature by having the air exchange heat with the fin and tube surfaces. Surface area is the important part with heat exchange situations. The more surface area, the faster you have a change.

A while back an article on reddit popped up that was talking about how to very quickly cool down a bunch of beer because throwing it in a bucket of ice didn’t work that fast. The problem with ice is that you have the surface of the ice cooling the surface of the beer or pop can. There are a lot of air gaps as well. This means not as much of the can surface area is being cooled as could be. Their suggestion in the post was to add some salt and water to it and make an salt water ice solution and put the cans in that. This rapidly changes the temperature of the cans because it has the temperature of the ice carried by the salt water fluid medium.

I was thinking about heat exchange at that time anyway and thought about surface area quite a bit and how you could achieve a good surface area. Then it occurred that if you are using a super cooled fluid that you could just pass bubbles through it and that the bubbles would float to the top of the water. This concept was being used in a previous homemade geothermal system I had designed. The idea in that design was to have a tank of water in the ground and bury one end in the water and the other end at the top of the water to get the air bubbles to pass through the water and do the thermal exchange. Bubbles can be very tiny and that tiny size allows for a spherical surface area. If you have ALL of the air you are trying to exchange made into tiny bubbles, it allows for an instance temperature exchange between the bubbles and the fluid it is changing temperatures with.

Cooling with Peltier Devices – Peltier devices are thermoelectric devices. When electricity is applied, one size of the flat device is hot and the other side is cold. You can read more about Peltier refrigeration setups here on Stack Exchange. You can stack them to amplify the effect as well to get drastic temperatures. For our purposes we want something that is well below 0 degrees Celsius, to about -30 degrees Celsius.

[youtube id=”7byTz2SFeck” align=”center” mode=”normal” autoplay=”no” maxwidth=”680″ grow=”yes”]

Insulation – The fluid tank will need to have insulation around it to keep it ready to go and to minimize the amount of time and energy that has to go into keeping the fluid very cold. Current insulation allows us some advantages. Aerogel is a NASA designed insulation that allows for very good insulation properties with little amounts of space needed for it. It was brittle and hard to work with. It works by being mostly air and trapping those air particles between solid matter so that the air particles are unable to vibration and thus cannot transmit heat through it very well. For instance you can put a chocolate on top of a wafer of the Aerogel insulation and put the torch of a propane torch a the bottom of the wafer and not have a problem for quite a while.

The insulation has been used in its modified form on a cooled container in an ocean going ship and then turned off the cooling units and the temperature only dropped by 1 degree in a 24 hour period. That means it should work out pretty well for keeping the tank cool. Cryogel will be used as it is meant for cold and is flexible and hydrophobic which is important with insulation. You don’t want water being trapped in insulation, but some kinds will do that.

Initial Technology Options

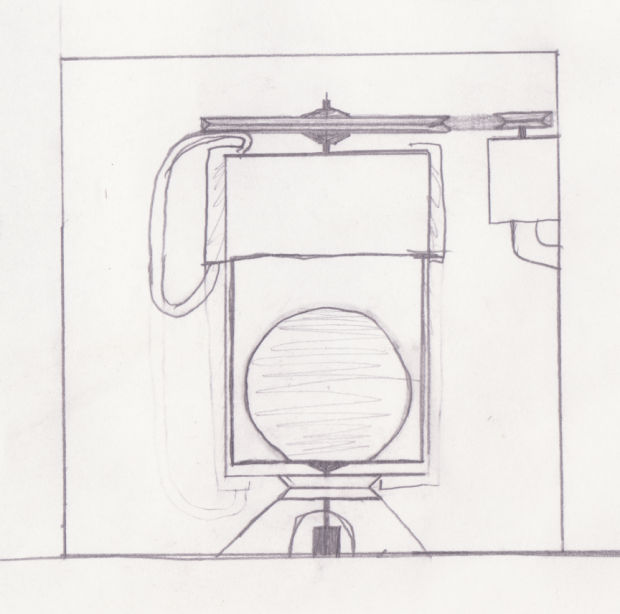

This was to figure out where the physical locations of the convection tubing should be placed for maximum effectiveness.

Rough mockup of insulation, integrated water tank, and located tube ends.

How to make the tank and pump small enough to integrate into an actual microwave to retain the microwave ability as well.

The impeller air pumps are loud and can have their sound dampened as long as the air ports have the sound dampened for those places. This is done in this sketch by trapping the sound between water tanks.

First build of the Super Freeze

VERSION 3 – FUTURE VERSION CONCEPT

A microwave works by using radiation to induce molecular vibration increases to increase the heat.

[youtube id=”Jwxm-9X7DZE” align=”center” mode=”normal” autoplay=”no” maxwidth=”680″ grow=”no”]

It would be great if you could cool as well as heat with a microwave. How would we do that when it seems you can only add energy to molecular systems. Not exactly true. Think about a swing. When someone is swinging you can push at specific times to add energy to their swing in the direction you are swinging them. They will go higher and higher if the energy is added at the right time as usual. You can remove energy as well however by doing the push at the right time and suck up a bit of energy. Scientists have figured this out over the years and took the method and made a laser cool matter to as close to absolute zero as you can.

Laser Cooling

[youtube id=”fZ95M85rHxg” align=”center” mode=”normal” autoplay=”no” maxwidth=”680″ grow=”no”]

A laser however is composed of light and stops at the surface of materials. That won’t help us except to cool the surface of things. What does work? Sound and radio waves both pulsate with wave forms and both can interact quite well with materials. Ultrasonics can be quite powerful when you point them at the same spot with the same frequency so that the power adds up at that specific location. This has been used to break up kidney stones. The radio waves we already know are used in the microwaves to heat things by interacting with the materials structure.

Using this method, you could modify the microwaves or ultrasonics to apply the same laser cooling effects that the laser cooling uses but to the food. This way you could reuse the magnetron in the microwave that is used to create the microwave radio waves that generally heats your food or drinks.

The idea with the ultrasonics is to match the resonance of the water in the material and then you can modify the speed of the materials structure slower to cool it. If it isn’t something with water, you could have it check the resonance of the objects major material composition. Ultrasonics were chosen because it has the ability to move very fast at speeds that most likely would be needed to induce vibration change of the materials.

General Electric has been working on a technology that uses magnetics to do the cooling.

General Electric Magnetic Cooling

[youtube id=”WlKKKMTA7XM” align=”center” mode=”normal” autoplay=”no” maxwidth=”640″ grow=”yes”]